About Us

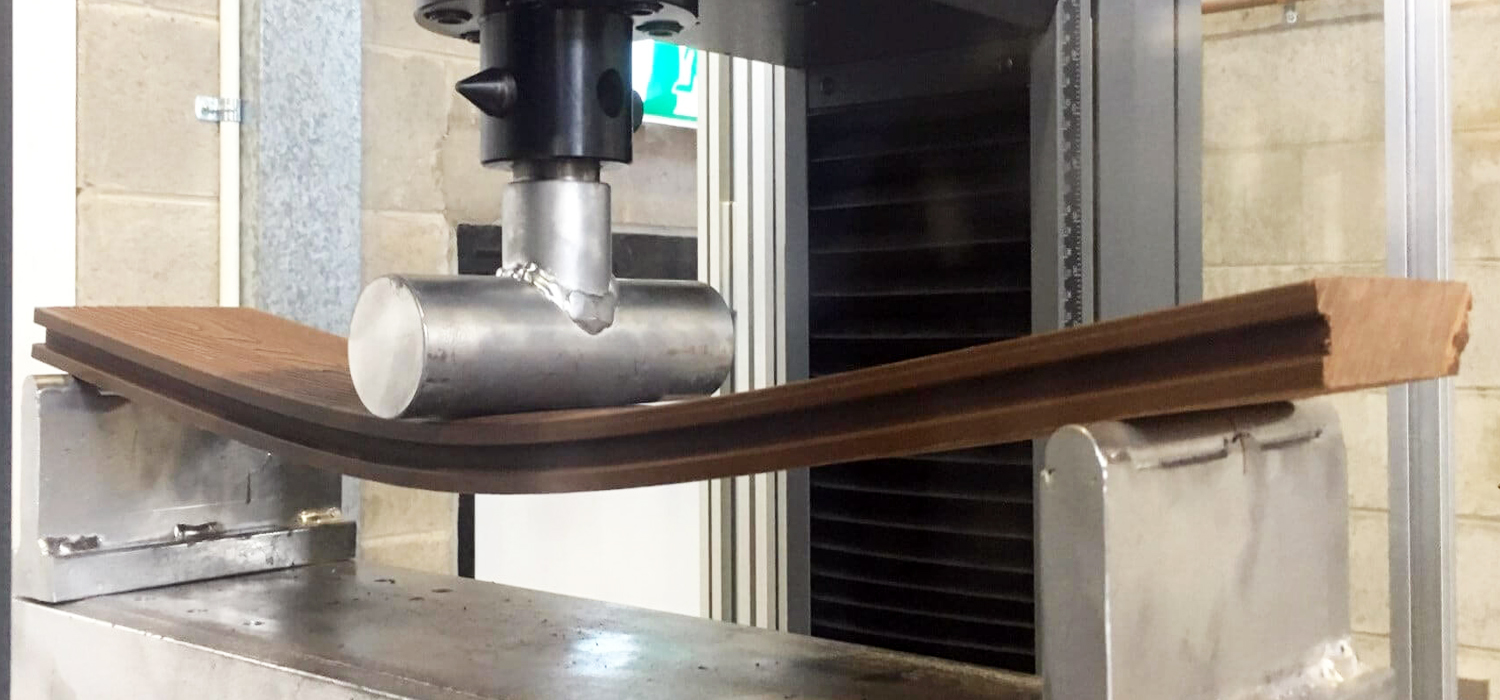

Welcome to Universal Testing & Research Centre

Our knowledge at your service

Universal Testing & Research Centre (A division of Sustainable Stewardship Private Limited) was started in 2019 to cater to the testing requirements of the wood industry. Although, the wood industry today caters to a huge product segments, however absence of an integrated single point testing facility posed a challenge to those to wish to go beyond the norms and do some path breaking work in the field of sustainability and compliance requirements. With a vision to address such requirements of the forerunners and torch bearers of the industry, Universal Testing and Research Center has been established.

The lab has been awarded with ISO 17025:2017 and BIS (Bureau of Indian Standards) accreditation that provides unmatched testing services with crisp price points and superior delivery for providing Testing Services for the below wooden products. Hence, without a doubt Universal testing and research center is an unmatched future partner for your testing needs.

Our team of experts, having intensive understanding of the implication of test results, hence utmost care is taken to ensure that our tests not only follow stringent standard protocols, but also ensure that personal attention is given to each test conducted in our lab We help firms achieve their quality and regulatory standards, preserving brands, assisting them in responsible growth, and assisting them in providing assured quality to consumers.

Services

Test for Block Board as per IS 1659

Block boards are being used in increasing quantities in the construction of railway carriages, bus bodies, marine and river crafts and for furniture making, partitions, paneling, prefabricated houses, etc. Block board is a board having a core made up of strips of wood, which may or may not be glued together and the core is glued to two or more veneers, on either side with grain direction of core and veneers running at right angles to one another. It can be of two grades i.e. MR & BWP grade and two types i.e. Commercial & Decorative.Test for Fire Retardant Plywood as per IS 5509

Plywood is similar to solid wood of comparable density and thickness in its behaviour towards fire. Fire retardant characteristics is a very important property to prevent propagation of fire at the initial stages. Being an organic material, plywood cannot be made completely fireproof. However, its resistance to ignition, surface spread of flame, flame penetration, etc., can be improved by suitable treatments. For certain uses, for example, in ship building and railway coach construction, plywood treated against fire is required.Test for Marine Plywood as per IS 710

Plywood used in construction, repair and maintenance of marine and river craft is required to withstand rigorous conditions involving changes in temperature, humidity and alternate wetting and drying. In addition, they also need to withstand attack by marine organisms. Plywood used for general purposes is found to be unsuitable for such applications. The method of manufacture of marine plywood had been specifically stated in the standard so that the resulting plywood is capable of withstanding the rigorous conditions which marine plywood may have to withstand.Test for Shuttering Plywood as per IS 4990

Plywood for concrete shuttering works is a BWP grade plywood, preservative treated and specially suited for use in concrete shuttering and form work. Concrete shuttering plywood is very economic as it can be put to repeated use, depending upon the care taken during erection and dismantling. The main requirements of such plywood are that it should be durable under alternate wetting and drying conditions, its surface should be hard and it should possess adequate strength to withstand the load of concrete and the forces caused by pouring of concrete and vibrations.Test for General Plywood as per IS 303

Plywood for general purposes shall be of the following two grades, depending upon the bond strength developed by the adhesive used for bonding the veneers: a) Boiling water resistant or BWR Grade, and b) Moisture resistant or MR Grade.Tet for Structural Plywood as per IS 10701

Structural plywood is a speciality plywood different from other grades and types of plywood as covered by other Indian Standards. In this plywood, apart from the use of higher grades of adhesives (BWP type), special emphasis is laid on the species of timber to be used, the veneer quality and most importantly on the construction details to be observed in the manufacture of the plywood. The basic design values to be used in structural applications have to be evolved separately from the basic strength values depending upon the type and nature of application.Test for Pre Laminated Particle Board as per IS 12823

Pre laminated particle board in a particle board laminated on both surfaces by synthetic resin impregnated base paper under the influence of heat and pressure; or with finished foils under the influence of pressure or pressure and heat depending upon the type of binder used.Test for Particle Board as per IS 3087

A board manufactured from particles of wood and other lignocellulose material in the form of flakes, slivers, shavings, splinters, granules agglomerated, formed and pressed together under heat and pressure by use of an organic binder together with one or more additives like wax, preservatives, catalyst, etc.Test for Veneered Plywood as per IS 1328

Veneered plywood is used in paneling work in buildings, interior lining of railway coaches, buses and ships and for furniture and general interior decoration. In view of the wide field of its application, decorative plywood has to be durable, of sound construction and highest quality.Test for Medium Density Fiber Board as per IS 12406

Medium density fibre board is a panel product manufactured from lignocellulose fibres combined with synthetic resin or other suitable binder. The panels are manufactured to a specific gravity of 0.6 to 0.9 by the application of heat and pressure by a process in which the inter fibre bond is substantially created by the added binder. Other materials may have been added during manufacturing to improve certain properties.Test for Pre-Laminated Medium Density Fiber Board as per IS 14587

Pre laminated medium density fibre board is a medium density fibre board laminated on both surfaces by synthetic resin impregnated base papers with or without impregnated overlay under the influence of heat and pressure.Test for Timber / Wood as per IS 1708

The evaluation of basic properties of timber, such as strength, density effect of various treatments on strength, etc., and the establishment of design functions for structural timbers has been done on the basis of tests carried out on small clear specimens of timber.

ASTM 6007-14 (Small Chamber method)

This test method measures the formaldehyde concentrations in air emitted by wood product test specimens under defined test conditions of temperature and relative humidity. Results obtained from this small-scale chamber test method are intended to be comparable to results obtained from testing larger product samples by the large chamber test method for wood products.EN 717-1: 2004 (Wood Based Panels – Determination of Formaldehyde Release)

This standard specifies a chamber method with three options of test chambers for the determination of the formaldehyde emission from the wood based panels in terms of steady state concentration in a climate chamber under defined conditions.ASTM 5582-14 (Desiccator Method)

This test method covers a small scale procedure for measuring formaldehyde emission potential from wood products under defined test conditions. The formaldehyde level is determined by collecting air-borne formaldehyde in a small distilled water reservoir within a closed desiccator.JIS A 1460:2015 (Desiccator Method)

The test for determination of quantity of formaldehyde emitted from building boards by desiccator method is carried out by using the glass desiccator. The emitted quantity of formaldehyde is obtained from the concentration of formaldehyde absorbed in distilled water measured 24 h under the controlled temperature.BS EN 12460-5:2015 (Perforator Method)

This method is used for the determination of the formaldehyde content of unlaminated and uncoated wood based panels. The formaldehyde is extracted from test pieces by means of boiling toluene and transferred into distilled or demineralized water. The formaldehyde content of this aqueous solution is determined photometrically.IS 13745 (Perforator Method)

The determination of formaldehyde content of wood panel by an extraction method known as Perforator Method. The formaldehyde is extracted from test pieces by means of boiling toluene and transferred into distilled or demineralized water. The formaldehyde content of this aqueous solution is determined iodiometrically.

Formaldehyde concentration test as per IS: 3321

This standard allows to determine the acidity, ash, aldehyde content & methanol content from the formaldehyde solution under the controlled temperature conditions.Phenol purity test as per IS: 538

This standard allows to determine the purity of phenol by bromide-bromate solution method. The method is based on the reaction between phenol and bromine from standard bromide-bromate solution.

Universal Testing & Research Centre (A division of M/s. Sustainable Stewardship Private Limited), accept the sample from different cities of India like South Delhi, Ananthapur, Cuddapah, Goa, Chamba, Kullu, Mysore, Idukki, Thiruvananthapuram, Ludhiana, Hyderabad, Visakhapatnam, Chirang, Karimganj, Aurangabad, Bhojpur, Gopalganj , Muzaffarpur, Balrampur, Ahmedabad, Ambala, Yamuna Nagar, Kinnaur, Kinnaur, Bokaro, Bagalkot, Bangalore, Lakshadweep, Agar, Aurangabad, Meerut, Ghaziabad, Agra and conducting Bath Soap / Hand Made Soap / Toilet Soap Testing as per IS : 2888, IS : 13498 and EN : 13697 which includes as below:

- Fragrance,

- Humidity,

- Dimension,

- Texture,

- Effects of Humidity,

- Total fatty matter,

- Rosin acid,

- Free caustic alkali as sodium hydroxide (NaOH),

- Matter insoluble in alcohol,

- Chloride (as sodium chloride),

- Free carbonated alkali,

- Lather in ml,

- pH,

- Mush,

- Freedom from grittiness,

- Freedom from cracking,

- Cleaning efficiency,

- Synthetic surface active agent,

- Germ Kill Efficacy Test

For more information please write to us lab@universaltesthouse.com

Universal Testing & Research Centre (A division of M/s. Sustainable Stewardship Private Limited) are and samples can be sent from any city like, North Delhi, Amritsar, Ferozepur, Ajmer, Alwar, Barmer, Sikkim, Ariyalur, Chennai, Dhalai, Gomati, Aligarh, Allahabad, Amroha, Azamgarh, Ballia, Tehri Garhwal, Uttarkashi, Kurnool, Nellore, Visakhapatnam, Anjaw, Changlang, Dibang_Valley, Baksa, Barpeta, Bongaigaon, Araria, Arwal, Chandigarh, Balod, Baloda_Bazar, Balrampur, Amreli, Anand, Bhiwani, Faridabad, Kinnaur, Lahul and Spiti, Anantnag, Badgam, Bandipore, Bokaro, Chatra, Deoghar, Bagalkot, Bangalore, Anuppur, Akola, Bishnupur, Chandel, Churachandpur, Bankurafor and conducting testing of Bathroom Cleaner testing as per IS : 12767 which includes:

- Sediment,

- Total fatty matter,

- Unsaponified and unsaponifiable matter,

- Free caustic alkali,

- Chloride (as Kcl),

- Free fatty acid,

- Matter insoluble in alcohol,

- Drop test,

- Efficacy,

- Leakage,

- Stability test,

- Brookfield viscosity,

- Fragrance,

- Specific gravity,

- pH,

- Tough stain removal mass,

- Germ kills,

- Effect of Humidity

For more information please write to us lab@universaltesthouse.com

Universal Testing & Research Centre (A division of M/s. Sustainable Stewardship Private Limited) are and samples can be sent from any city like, Aizawl, Champhai, Kolasib, Dimapur, Kiphire, Kohima, Angul, Balangir, Baleswar, Karaikal, Mahe, Yanam, Ajit Garh , Amritsar, Bathinda, Banswara, Ariyalur, Coimbatore, Karimnagar, Khammam, Mahbubnagar, Dhalai, Gomati, Khowai, Agra, Almora, Bageshwar, Chamoli , Alipurduar, Bankura, Barddhaman for conducting Bathroom Freshener block and conducting testing as per IS : 11355 and IHTM which includes:

- Workmanship,

- Functionality,

- Dimension,

- Drop Impact Test,

- Colour,

- Weight loss,

- Odour/Flavour,

- Effect of heat,

- Effect of humidity,

- Hanging strength,

- Skin Irritation,

- pH,

- Volatile amines (As analine),

- End of useful life

For more information please write to us lab@universaltesthouse.com

Clients

Contact Us

UTRC IS PLEASED TO OFFER ITS EXPERTISE IN ANALYSIS AND RESEARCH IF YOU ARE SEEKING SOLUTIONS. WE ARE HERE FOR YOU

Our Address

487/59, GROUND FLOOR, NATIONAL MARKET, VILLAGE- PEERAGARHI, NEW DELHI, INDIA-110087

Email Us

info@universaltesthouse.com

Call Us

+91 9810124221

+919810557685